Technical Specifications

| Design Code: | EN 13458-2 |

| Design Pressure: | 16 / 17 / 19 / 37 bar |

| Test Pressure: | 25.5 / 25.74 / 31.86 / 54.34 bar |

| Design Temperature: | -196 / +20 °C |

| Capacity: | 2 m³ / 50 m³ |

| Material: | EN 10028-7 (SS304L) |

| Tank Type: | Cryogenic Storage Tank |

Details

- Project and calculation checks and approvals

- Chemical and mechanical testing of the material

- Separate material control and cold stamping

- Step-by-step inspection of production

- Dimensional inspection

- Radiographic examination

- Ultrasonic thickness control

- Penetration paint test

- Heat treatment

- Hydrostatic test

Cryogenic Tanks: Safe Storage and Transportation Solution at Low Temperatures

Cryogenic is a term used in physics for production and processes carried out at very low temperatures. Temperatures between -150°C and absolute zero (-273°C) are defined as cryogenic temperatures. These low temperatures play a critical role in the liquefaction of gases such as oxygen, hydrogen, helium, argon, and nitrogen.

Cryogenic tanks are specially designed and manufactured systems to safely store and transport these liquefied gases. By maintaining gases like liquid nitrogen (LIN), liquid argon (LAR), and liquid oxygen (LOX) at low temperatures, they play a vital role in industrial and scientific applications.

Features of Cryogenic Tanks

🔹 Double-Layer Vacuum Insulated Structure: Cryogenic tanks are produced with a double-walled and vacuum-insulated design to maintain the low temperatures of the gas inside. This structure minimizes heat loss and allows for the longer storage of liquid gases.

🔹 High Pressure Resistance: Since liquefied gases are kept under high pressure, cryogenic tanks are made using materials with high pressure resistance.

🔹 Special Insulation Systems: Special insulation materials are used to minimize heat transfer. This prevents the evaporation of liquid gas inside the tank, keeping it stable for a long time.

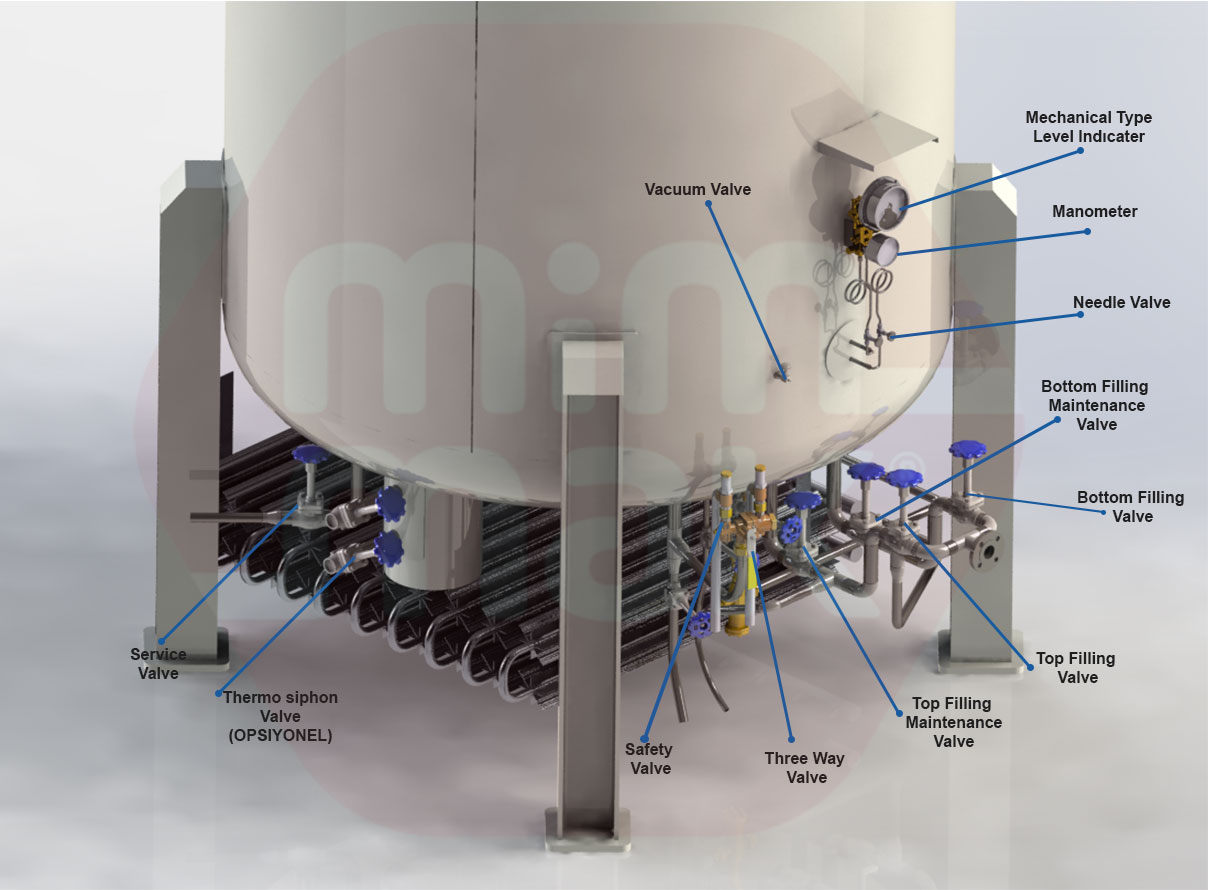

🔹 Safety Valves and Control Mechanisms: Equipped with safety valves and control systems to prevent the formation of excessive pressure, ensuring that the tanks are used safely and for a long lifespan.

Applications of Cryogenic Tanks

Cryogenic tanks have a wide range of applications in various industries:

✔ Healthcare and Medical Industry:

- Used for the storage and distribution of medical oxygen (LOX) in hospitals.

- Preferred for cell and tissue preservation in laboratory environments using liquid nitrogen (LIN).

✔ Industrial Manufacturing:

- Essential for the use of liquid argon (LAR) in welding and metal cutting processes.

- Used as cooling systems in production facilities operating at high temperatures.

✔ Food and Agriculture Industry:

- Liquid nitrogen is used for freezing food items and long-term storage.

- Preferred in the agriculture sector for soil gas analysis and biotechnological applications.

✔ Aerospace and Space Industry:

- Cryogenic hydrogen and liquid oxygen are essential for storing rocket fuel.

✔ Research and Scientific Work:

- Commonly used in experimental work in physics and chemistry laboratories.

- Cryogenic cooling is required in high-energy particle accelerators and superconducting systems.

Conclusion

Cryogenic tanks play a critical role in the safe storage and transportation of liquefied gases. With high safety standards, durable material structure, and efficient insulation systems, cryogenic liquids can remain stable for long periods and can be safely used in many different industries.

From industrial manufacturing to the healthcare sector, from aerospace to scientific research, cryogenic tanks have a wide range of applications and, with advancements in technology, continue to evolve as an innovative solution for the future.

Request a Quote

Do you have questions about how we can assist your company? Send us an email, and we will get in touch with you shortly, or call +90 (328) 826 81 11 – 12 between 08:00 and 18:00 from Monday to Friday – we’d be happy to talk.

Your information will be kept strictly confidential in accordance with our Company Privacy Policy.